Soldering is an essential technique in various industries, from electronics to plumbing, where two or more metal components are joined together using a filler metal. While the skills of a solderer play a significant role in achieving a strong and durable bond, the role of abiotic factors should not be overlooked. In this article, we explore the important role that abiotic factors play in perfecting the art of soldering. From temperature and humidity to cleanliness and surface preparation, abiotic factors can greatly influence the quality and reliability of soldered connections.

Achieving the optimum temperature is crucial to ensure proper solder flow and adhesion, while controlling humidity can prevent harmful corrosion on solder joints. Additionally, maintaining a clean working environment and preparing surfaces properly can minimize the presence of contaminants that could compromise the solder joint integrity. Understanding and managing these abiotic factors are vital for solderers to consistently produce high-quality connections. By doing so, they can ensure the long-term functionality and reliability of soldered components. Join us as we delve deeper into the fascinating world of soldering and uncover the secrets to mastering the abiotic factors that contribute to the art of soldering perfection.

Understanding Abiotic Factors in Soldering

Soldering is a key process in electronics and manufacturing. It joins metal parts by melting a filler metal (solder) at the joint. The soldering process may seem simple. But, many abiotic factors affect the quality and reliability of solder joints. Understanding and controlling these factors are crucial for achieving successful soldering outcomes. This article explores key abiotic factors. They are: temperature, humidity, air quality, surface cleanliness, ventilation, and soldering iron tip temperature. It examines how they affect the soldering process.

The Importance of Temperature in Soldering

Temperature is the cornerstone of the soldering process. It’s vital to reach the right temperature. It will melt the solder but not damage the components or substrate. Soldering typically occurs at temperatures between 180°C to 250°C, depending on the type of solder used. If the temperature is too low, the solder may not flow properly, leading to weak joints and cold soldering. Excessive temperatures can cause the solder to oxidize. This results in poor wetting and can damage sensitive components.

Maintaining a stable temperature is crucial. Temperature variations can cause inconsistent soldering results. So, it’s essential to use soldering irons or stations with precise temperature control. Preheating the components and work area can help. It can lead to consistent results, especially in complex assemblies.

The Role of Humidity in Soldering

Humidity is an often-overlooked factor in the soldering environment. High humidity levels can lead to the absorption of moisture by the soldering materials, particularly the flux. This moisture can cause spattering, which not only creates a messy work area but can also lead to the formation of voids in the solder joints. These voids weaken the mechanical strength of the joint and may cause electrical failures over time.

Low humidity can cause electrostatic discharge (ESD) events. These can damage sensitive electronics. Keeping humidity at 30% to 50% prevents problems. It reduces ESD risk for better soldering results.

Impact of Air Quality on Soldering

Air quality is another critical abiotic factor that influences soldering. Airborne contaminants, like dust and oils, can settle on the soldering surfaces and the soldering iron tip. This can harm solder adhesion and joint integrity. Also, airborne contaminants can react with the solder. They can form oxides and other unwanted compounds. These can harm the quality of the solder joint.

To maintain good air quality, it is important to work in a clean, controlled environment. Using air filters or solder fume extractors can help. They reduce airborne particles and contaminants. This ensures cleaner, more reliable soldering.

Significance of Surface Cleanliness in Soldering

Surface cleanliness is perhaps one of the most critical factors in achieving strong, reliable solder joints. Contaminants on the soldering surfaces, like oxidation or oil, can prevent proper wetting of the solder. This can lead to weak joints. Before soldering, clean the surfaces. This removes contaminants and ensures good solder flow.

We can use various cleaning methods. They include mechanical abrasion, chemical cleaning, and flux. Flux is very effective. It cleans surfaces by removing oxides. It also helps the solder wet better, making stronger joints. However, it’s important to clean the flux residues after soldering. They can be corrosive and may affect the joint’s long-term reliability.

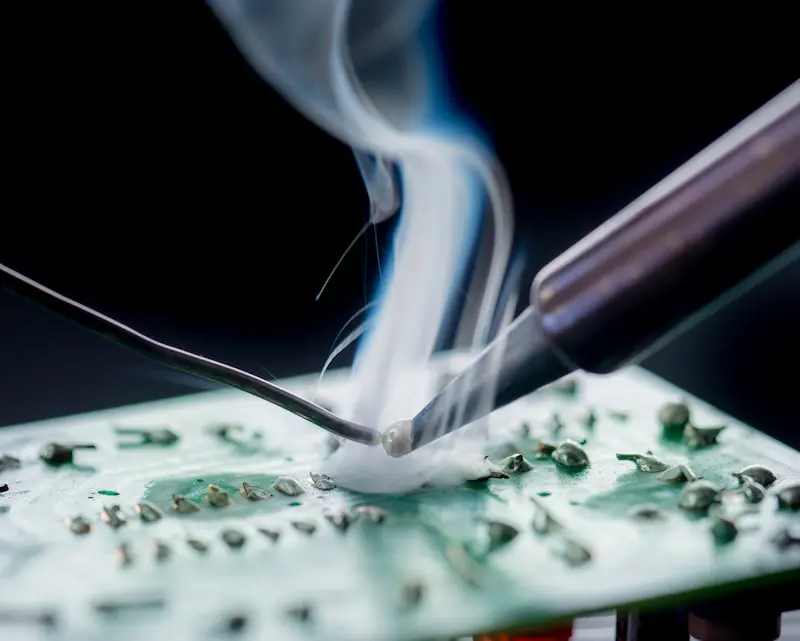

Considerations for Proper Ventilation in Soldering

Proper ventilation is crucial in any soldering environment. The soldering process produces fumes that can be harmful to both the operator and the components. These fumes can cause respiratory issues. They often contain flux residues and other chemicals. They can also contaminate the soldering surfaces.

Using a solder fume extractor or a ventilated area helps. It removes harmful fumes, protecting the operator’s health and keeping a cleaner workspace. Also, proper ventilation prevents heat buildup. It helps keep a stable temperature during soldering.

Effect of Soldering Iron Tip Temperature on Solder Joints

The temperature of the soldering iron tip directly affects the quality of the solder joints. A tip that is too cold will not melt the solder. This leads to weak joints. A tip that is too hot can cause the solder to spatter, oxidize, or even damage the components being soldered.

It is essential to select the appropriate tip temperature based on the type of solder and the components being joined. Regular maintenance of the soldering iron tip is important. This includes cleaning and re-tinning it. It ensures efficient heat transfer and prevents oxide buildup, which can hinder soldering.

The Role of Soldering Flux in the Soldering Process

Flux plays a vital role in the soldering process by cleaning the surfaces to be soldered and promoting better solder flow. It removes oxides from the metal surfaces, ensuring that the solder can properly wet and bond with the components. Flux also helps to reduce the surface tension of the molten solder, allowing it to flow more easily and form a stronger, more reliable joint.

Choosing the right flux for the specific soldering application is important. There are different types of fluxes. They are rosin-based, water-soluble, and no-clean. Each has its own advantages and uses. Proper use of flux can significantly enhance the quality and reliability of solder joints.

Tips for Optimizing Soldering Conditions

To get the best soldering results, optimize the conditions. Carefully control the abiotic factors discussed above. Here are some tips for optimizing soldering conditions:

-

Temperature Control: Use a soldering iron with precise temperature control and preheat components when necessary.

-

Humidity Management: Maintain humidity levels between 30% to 50% to prevent moisture-related issues and minimize the risk of ESD.

-

Air Quality: Work in a clean environment with proper air filtration to reduce contaminants.

-

Surface Cleanliness: Clean all surfaces before soldering to ensure good solder wetting.

-

Ventilation: Use a solder fume extractor or work in a well-ventilated area to remove harmful fumes.

-

Tip Maintenance: Regularly clean and tin the soldering iron tip to maintain efficient heat transfer.

-

Proper Flux Use: Choose the right flux for your application and clean any residues after soldering.

Conclusion: Harnessing Abiotic Factors for Successful Soldering

Successful soldering depends on controlling various abiotic factors. These include temperature, humidity, air quality, surface cleanliness, and ventilation. The soldering iron tip temperature also matters. Optimizing these factors will yield stronger, more reliable solder joints. This will improve the quality and longevity of your soldered assemblies. Whether you are a pro or a beginner, pay attention to these factors. They will help you master soldering and achieve high-quality results.